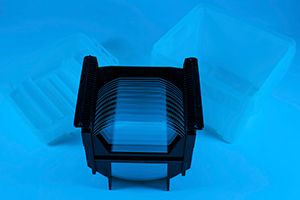

Custom Glass Wafers

Sydor Optics, Inc.

- Glass Wafer Manufacturing Limits (part size, material type and thickness dependent): - Diameter: ≤ 450mm - Thickness: ≥ 0.1mm - Thickness Tolerance: ± 0.003mm - Bow / Warp: ≥ 3μm - TTV: ≤ 1μm - Surface Roughness: ≥ 5 Å rms - Parallelism: ≥ 1 arc seconds - Cosmetics (MIL-PRF-13830B): 60-40 to 10-5 - Edge Exclusion Zone (Clear Aperture): ≥ 3mm - Transmitted Wavefront Error (TWE): ≥ 1/10 wave over 25mm sub-aperture - Reflected Wavefront Error – RWE (Local Site Flatness): ≥ 1/10 wave over 25mm sub-aperture - Bevels: 45° or c-bevel - SEMI Notch: yes - SEMI Flat: primary & secondary

*Manufacturer's specifications subject to change without notice.

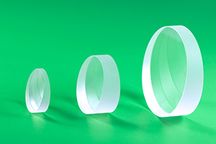

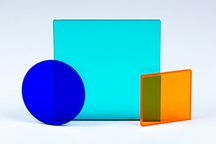

Sydor Optics is a custom manufacturer of precision flat-surfaced, parallel and wedged glass optical components specializing in double-sided polishing, continuous pad & pitch polishing, CNC machining and laser machining. Prototype to high-volume products include wafers, windows, filters, mirrors, optical flats, wedge prisms, light pipes, plate beamsplitters, and coating witness samples. Finished optical products go through a meticulous visual inspection process utilizing a wide range of state-of-the-art metrology equipment. Additional capabilities include ultrasonic cleaning in a cleanroom environment and cleanroom packaging. Sydor Optics is ITAR Registered and ISO 9001:2008 Certified.

View Products

Company Website

Contact